Hello, I received the improved version of the flexible TPU case (see the picture where I twist it). And I have to say that I am satisfied with it compared to the prototype.

For those who are wondering, it’s a TPU Multijet process with a chemical treatment finish.

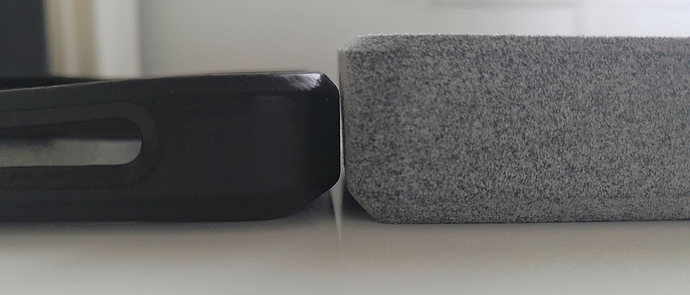

The point of improvement is the one I already imagined at the time: there is still a gap of 2mm vertical and 1mm or 2mm horizontal. It’s not a scandal because the phone holds in place but it is not firmly held in the shell. For the rest the holes are aligned, the thickness is much thinner than before and it doesn’t feel like it tears easily. Here are some pictures with comparison between prototype and @fiacco improvements, hoping that @fiacco can help us to update the STL file for a final version :

In any case, a HUGE thanks to @fiacco and all to all those who helped to improve the concept.