Nope. Just Firefox

On Tor:

put that on ebay or amazon and I am buying it. Give it an adjustable kickstand piece, I will even write a positive review!

Absolutely. Will do it tomorrow evening, when I have it on hand again.

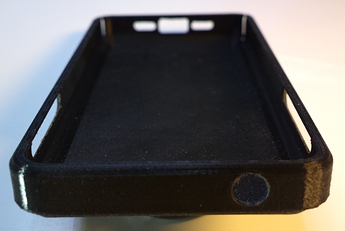

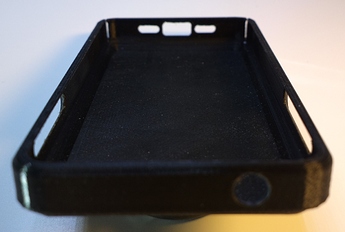

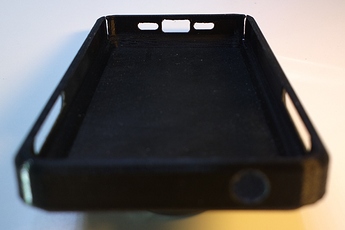

And quick update on the 2.0.2 version: I had it printed and it looks good. All the holes align nicely and it looks very slick in black. The printer did fuzz te edges a bit, so I need to use knife, level and file a bit, and I need better lighting to get pics, so full report tomorrow. ![]()

![]()

![]()

Hello, in my proto, it was clear that the shell added thickness to the phone (which is already very thick). Aesthetically, I didn’t imagine using this shell outside.

Now improvement has been made, what is your objective feeling about this ? (I mean, pictures are promising, but real life feedback is better)

Is it “the shell adds more thickness, it’s bigger” or is it discreet, skinny?

Thank you !

So… Black makes the case (and L5) look cool (cooler)

Impressions… As L5 is already hefty, the added case actually doesn’t feel like it’s adding mass or size. With the printed rigid type case it feels protected. But there are a few caveats that I come in a bit. Before that, I just have to say how well the case seems spot on, really hugging the phone - any variation you want to do, this seems like a good base for forks (for TPU/flexible materials, a version without the slits is needed [or, if you are in a hurry, you can glue these shut]). [edit to add: depending on you preference, sides could do with some groove/diamond pattern for grip]

Some minor adjustments are needed (there is a little round hole missing from the top: 3mm diameter hole, center of hole should be about 23mm toward center from audio hole center and on the level of audio hole lower edge). Other than that, existing holes for all L5 features are where they should be and are usable [individual printers may have trouble with making inner top edges of holes so minor finishing touches may be needed].

Firstly, the caveats from the rigid print material perspective. This variation model works but I can only recommend it “as is” to someone who want’s to put their L5 in a case and never take it out. It may take a minute or two to pry it out with out damaging phone or case. The major sticking points are the buttons on the side, as they do not slip in and out. It may be possible to modify this so, that the upper edge of the sides is removed from the middle third (with some cost to how durable the case is and how the edge looks like). Even with the enhanced sides I still managed to split a print layer while trying to remove the once (luckily nothing broke off, easily glued). The slits for this version work but are a bit too narrow, as the print material sticks and almost fills them, so the width should be maybe double (depending on printer accuracy, may need to use knife). Major redesign idea would be to add a big oval hole (about 3x5cm) for a finger (approximately in the middle or a bit lower) to be used to poke the phone out. Secondly, see my later notes on the heat issue. All in all, it’s a good version that works and looks pretty, but there are usability issues.

I re-did my previous rapid development idea and removed the ends - this time more cleanly - and I like how it works compared to the full version. This version extends beyond all axis just as well as the full version versus a drop to the floor or other flat surface. Because the phone is MUCH easier to remove from it, this will probably end up as my current case (it fits to the molle/tactical belt pouch) as is [ “as is” = spent 10mins after printing removing excess extrusions with a knife and filing down uneven spots etc. that various printer do regardless of design] or finishing off the surface. [edit: sorry, no pics yet of this variation]

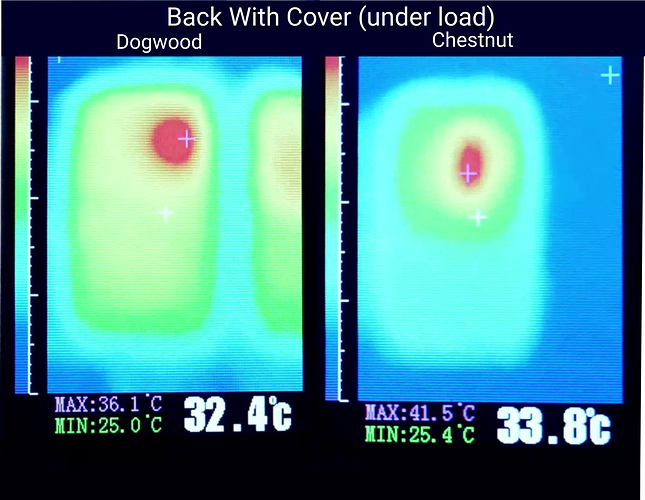

I did some testing with heating furnace… I mean thermal properties of L5. I measured about 45mins (0, 15, 45) taking IR measurements from case surface while the phone was under load (charging + web browser + streaming music via wifi + sudoku + usage statistics running… about 2/3 cpu and memory load, while charging contributing heavily on the heat IMHO). Measured from A) three spots on screen centerline (25%, middle, 75%), B) both sides (middle and lower 75%), C) back (centerline middle and lower 75%). And also noted what the Usage thermal measurements showed.

I*ll spare you the suspense: this setup lit the red temperature warning light and I’m not sure when it lit up. I haven’t had time to figure out what would be a reasonable load without a case not to cause that, so I may have over done it a bit. In 15mins the cpu/gpu/vpu temps were around 49C and at 45mins 54C, and charger went to 38,5C and 44C. This is all rather meaningless however, because I was not able to get very accurate comparison data. Without the full case [note, back was against the table, so similar to being in a case], with similar load, Usage displayed about 50C temperatures at 15min mark, about 52-53C at 30min, and at 45min mark seemed similar to previous. Even at 60mins it did not reach warning light level, always about two degrees below case temperatures. Screen measurements were about a degree, or even more, less than with case. This all seems to indicate that the full (or any) case is not advisable with heavier use and simultaneous charging (unless the case has some active cooling).

All that being said, the case seems very good at this point. Size 80,5mm x 158mm.

[edit to add: at 0.27mm layer resolution this one took about 4 hours, definitely could make better if you had more time and used finer detail resolution settings]

Inner profile seems perfect from the cuts too:

Would a matrix of holes on the back and sides help? I’ve never 3D printed anything so maybe it would be too much for the printer, but it ought to help with flexibility too if it can be done.

I’m not sure. Maybe. But more likely… or more beneficial… would be to have material that conducted heat away (instead of insulating and accumulating it) or some active component (attach a fan - I’m afraid these exist). The back may not be the most troublesome however: the back cover could be removed from between the phone and the case (in some design version of the case), so, having the case attach directly to the back with out it - that could open op more possibilities on removing heat (or at least more than what holes might. Then again, it’s not difficult at all for the printer (more maybe to the designer) and it’s also easy to test with a drill…

Thank you very much @JR-Fi for your complete feedback, I see the cuts, measurements and so on and I think it is not easy to take time to report all of this, so a big thanks for what you did.

I think in terms of rigid case, it can be interesting to imagine a system allowing to fit different parts of the shell in order not to destroy it during the installation or the removal of the phone. A kind of shell in 2 or 3 parts coming to clip solidly the ones to the others around the phone.

On my side, from all these conclusions, I think I’ll go back to this previous proposal of friend @fiacco (and not the last version by @JR-Fi, better for rigid cases), because the design and the thinness seems to me more appropriate to the TPU material.

And I don’t know if it’s possible but I would like to add ventilation holes at the hottest place to dissipate the heat a bit better.

Here is a thermal picture of the back of Dogwood (I didn’t find for Evergreen, but it seems to me that the PCB change was between Chesnut and Dogwood which shares more or less the same layout as Evergreen, correct me if I’m wrong). You can clearly see a heating on the SoC side, with the rest of the heat being dissipated to the screen. I think that obstructing this heat area and having a large thickness at the back prevents an optimal dissipation :

From there, here is my proposal (in red) based on the photo of @JR-Fi (remember that Dogwood’s thermal photo is seen from the outside back, while @JR-Fi 's photo is seen from the inside hence the fact that the holes look like they are in the opposite direction, but in reality are on the same side).

3 large holes in the shape of the other holes on the sides of the device, letting the heat escape and separated by a spacing easy to print unlike honeycombs and other complex shapes :

@fiacco , what do you think, do you still have the desire/time to add these holes to this particular STL version?

I’d love to hear your opinion, and based on that, I hope to launch my final TPU shell. Thank you !

Just to add that the Red Temp mean what is the heat source like CPU, so on Evergreen and Dogwood the CPU it to front to the monitor what helping to dissipate temperature by monitor, as the L5 has a dedicated monitor to support high temperature fluctuations. So in this case not need to make holes on the back side of cover, it make more sense make holes on the sides os frames then will help to dissipate temperature and at same time grid improvement. ![]()

Also remember that the L5 still not optimized 100% so the current temp it not real and will more coooler.

Thanks for make this project a reality, i want one good cover to my L5.

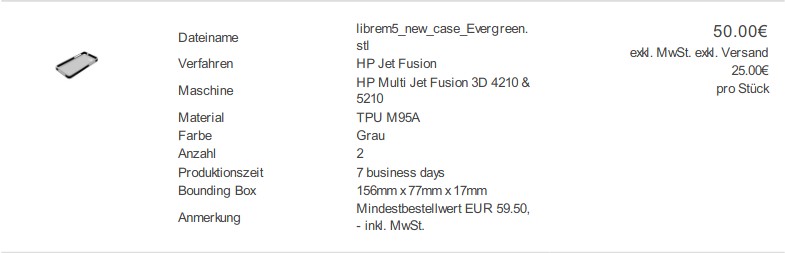

@fiacco, I’ve downloaded the above file on April 29 and got now an offer for printing it. See details in the picture. Before spending the ~74 euro, I wanted to ask you if this is the “final” file good for TPU or is there any better version? Thanks

The text in the offer is in German, but I think it’s clear what they mean. Color is grey.

No, it isn’t. I’ve to transpose the adjustments suggested by the firsts rigid prototypes. Be patient, tests are still ongoing.

Ok, thank you. Could you please put some version-number in the name of the file. Thanks again.

Do you need any more measurements or tests from the rigids? I know the wall thickness will need print tests to find a good balance, as printed is not the same as molded (which can have thinner walls and still be better).

Also, I did a quick test with the full rigid case, and had interesting result: I removed the back cover and added a couple of small peaces of foam double sided adhesive to make up for the missing thickness. Now the phone seems to work great under similar load to previous. Promising, considering how to design a case that allows for heat to dissipate…

Ay, the sides and metal transfer heat. The standard back cover may also prevent heat from leaving the phone. There are several variations to try.

Btw. I tested leaving the phone on and put it in a case inside the belt pouch - it got hot fairly quick (very nice at wintertime under the jacket at -20C…

After the suspend is enabled and optimized, this problem, too, will likely resolve itself.

No, thank you … in the pile of posts I’ve missed your review with the last model, I was waiting for it. I’m adjusting the rubber case model based on the last inputs.

Just noticed, on your offer, there is material marked TPU M95A. That 95A (possibly with M being a modifier) is the Shore hardness scale (see comparison chart or this one or this). You may want to make sure 95A is flexible enough - or just the right flexible. The printing service may be able to estimate that. To me it seems that may not quite be flexible enough (but I admittedly have little experience with flexible materials, just estimating from written descriptions). I’d probably go for 60A or even a bit lower. Do they offer other TPU hardnesses?

[edit to add: 95A is described as hard rubber (not very flexible), while 40A is closer to inner tire rubber.]

If the side metal it transfer heat then no need make holes because the case already accepting heat from metal side, so if you want stop transfering the heat from side metal to case then you need to use a different material to build the case like isolated material.

It is because the cpu it inverted to monitor with paste, so very sensitive heat, yes good L5 feature to wintertime. ![]()

Here the final models (this time using skynet, as suggested by someone before, hoping that it doesn’t gain self-awareness):

v.1.1 rubber case

https://skynet-send.hns.siasky.net/#b-AAD-lZW0EF5OFRto-Dx3H3-9T2aX4ojS5aJgGS0VDBtW_Q+ZXbQpn84XoT7J+P2+JFAYNFYQLv3kSFq+qqb6IwownVThKQuT1VJj/R3sZHfAwkR

v.2.0.3 rigid case

https://skynet-send.hns.siasky.net/#b-AADe7gsigNQqX86suQh0QL4Ryb0OkqYp-cGzJ6AeYqP4uQ+dnJMgOfttvtZdTHfUW0uO5c2hZDeThA+CO3y38BGiSKZDOmJJu+BYo0jc9uJNqXB

The last is the one tested by @JR-Fi, with splits width increased, upper hole added and cooling holes (not sure they will cool down but they are cool).

The first incorporates all the modifications except the increase of thicknesses and internal dimensions (which are the same as measured on my phone, making it pretty snug). I do not exclude that further adjustment may be required.

I am in front of a dilemma : the first flexible version (because of the tinnier dimensions) or the v1.1 (because of the back hole)… I think I shall sleep and decide not know, it’s wiser ^^

Again thank you for hashing shared all those jobs and knowledge !