Yes and yes:

Oh thanks, I missed that!

For a hard case, I wonder if putting a sheet of metal (like a heat sink) in between the case and phone would help at all.

Or maybe remove the plastic back case entirely, and have the “heat sink” right next to the phone components (but I can’t remember if there’s any circuits exposed that would be a problem)… so put some kind of non-conductive thermal transfer pad in between to transfer heat into the “heat sink” better?

Now that we’ve got Librem 5 3D models, maybe that helps improving or creating cases.

Oh cool, official ones? Is it more accurate than the one on this site? Files · master · Librem 5 Case Creating Community / Librem 5 model · GitLab

It’ll take some time before I make any progress (inexperience) but I’m working on this stuff to see if I can come up with anything useful that’s different from what’s been done already. I want to see if anything can be done to keep the phone cool while also protecting the user from sensing heat.

I also wonder if we can do a mega-thicc case which brings a huge upgrade to the battery and maybe even add some active cooling and/or a heat sink. I’ve seen someone with a regular phone before that was WAY thicker than an L5 due to some major battery upgrade, so I know it’s been done before. And I wonder how much heat comes from the battery itself? Would retrofitting a battery that has a larger capacity reduce that at all?

Lots of crazy ideas (probably infeasible but it’ll be fun to try anyway)… I just wish this thread was as active as it used to be.

I did some research into the “best” (materials for) phone cases, plus additional critical thinking, and have some solid suggestions:

- Raised lips and corner bumpers for front screen protection of the Librem 5.

- Button protection that provides tactile feedback.

- Switch caps for the hardware kill switches indicating an orange colour when toggled downwards.

Here are some other speculative ideas that may or may not be of value:

- Kickstand.

- Slim wallet case.

- Accomodation for additional accessories (breakout board, magnetic mount holder).

If you decide on using metal as a phone case material, you will want to design it so that it does not interfere with the cellular antennas or Wi-Fi/Bluetooth connection under normal operation.

I don’t know. There is already a dedicated thread to the STEM file release article.

Just in case: You know such pads exist, right? I think that is what you meant. Like those pads to transfer heat from a CPU to a heat sinks. Recently I notices that they are also available as adhesive tapes.

There are thermal

I’m not as worried about protecting (my own) from physical damage since I’ve never broken or even damaged a phone before, ever. Anything that protects from damage is a bonus. Heat management is what I want to focus on, with maybe the fantasy of an auxiliary battery and some physical protection as secondary.

I guess all this stuff is possible in theory, but actual hands on engineering tends to bring your ideas back down to Earth.

Yep, the stuff they shove between heat sinks and electronics is what I was thinking of.

Metal would be the material you would want to work with for heat dissipation. I would probably focus on attempting to replace the plastic back cover first with a metal variant to minimize expenses and whether or not the idea is feasible before considering a full encasement. There may be other design optimizations that can be done with the Librem 5 internals if you want to dig deeper into the issue.

Here we go… we need one of these 4mm fans embedded into the case:

That would mean it needs to be at least 5/6mm thick, or more. But at that thickness, I wonder if it’s possible to “engineer it” so a double-thick battery can go in place of the normal one, replacing the normal back case cover entirely.

Double battery capacity (or more) plus active cooling, and a cooler phone, just by going thicc. Which might seem weird, but there are those Android phone battery cases you can get which also turn a phone thicc! So we’re still within the bounds of normal! (Right? …Right??)

Powering the fan would be challenging though. Maybe a 4th “kill switch” for the user to manually toggle it? It’s too bad the L5 wasn’t built with Raspberry-PI like I/O pins… (You reading this Purism… V2 maybe? ![]() )

)

Okay… maybe the fan and even the battery thing is too much, but I am still going to try doing a case with better cooling.

Bad idea if you still want to make calls etc. If you just use it as PC replacement without any wireless connection - go for it. Or reroute the antenna somehow outside. But signal strength was one of the main reasons for the plastic cover as far as I know.

Already addressed:

Coming very late to this.

Seeing as though I will be using my L5 as my daily phone I need a case. I see that people have been ordering them in this thread. Can a kind soul point me to a link for such a thing? My search for this was a nightmare and I’d love to get some type of case for it.

OMG! So in theory… maybe an active cooling fan case is possible…?

So you’re telling me there’s a chance…?

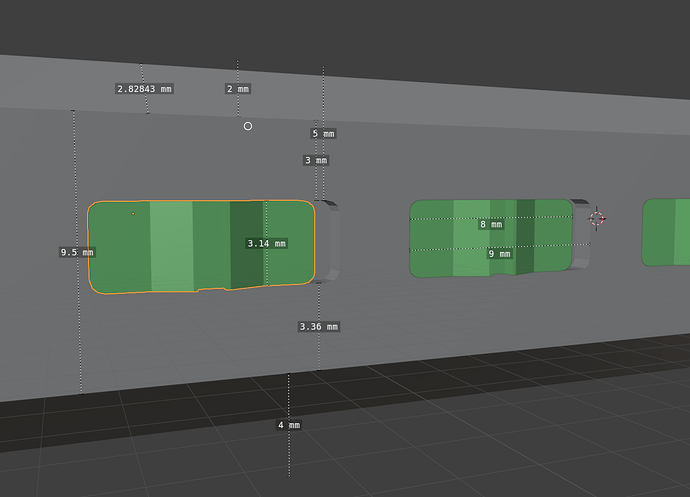

Having way more fun with Blender than I should be while messing with this.

I think it’s safe to say that I’ve gotten completely sidetracked with trying to improve the accuracy of the phone model… just to be used to assist with case design.

Don’t think ever I’ve had to use digital calipers or a dial indicator gauge to this degree. I mean this is just silly, trying to make this model accurate to .1mm. ![]() … WHY? lol

… WHY? lol

I’ve already (wasted time) replaced the kill switch buttons with realistic versions, fixed some differences with the power/volume buttons, cleaned up the model’s geometry some, and fixed up the cameras so they’re slightly recessed instead of protruding.

Oh wow look at this (sorry for bad lighting)…

Did a basic cutout for that (possible?) hotspot. TBH I’m not sure it is that hot, maybe it moved in the Evergreen edition?

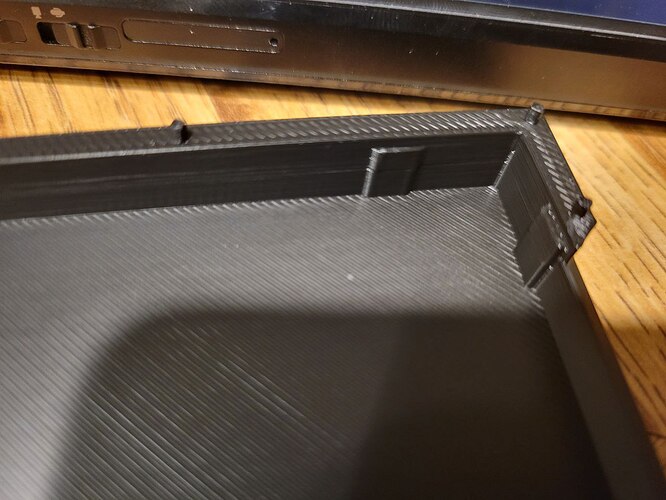

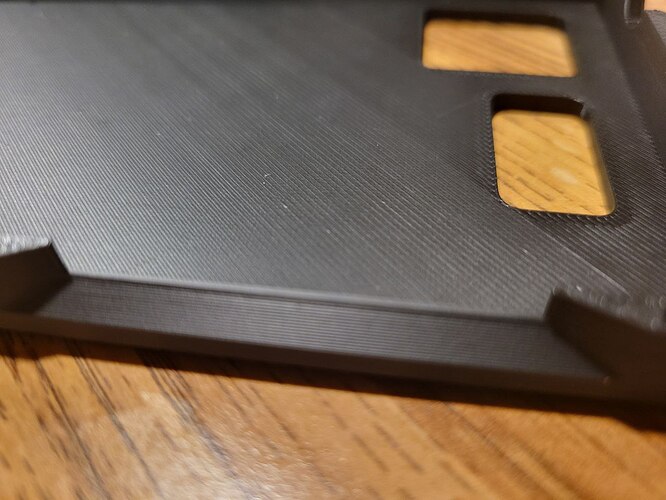

Instead of doing a “slide on horizontal” design like I was originally thinking, where I’d have to find a way to deal with the buttons blocking such a maneuver, I found that a horizontal slice works out much better for 3D printing. I was still concerned about how I’d attach the thing, but it turns out the software I’m using has a feature which generates these little attachment pegs for you. I will try some tweaks, but it worked out pretty good and is actually enough to keep the case on alone.

You can see I “cheated” a little and only added these little spacer tabs on the edges to adjust the fit after the 1st try. A little extra spacing between the phone and the case might not be such a bad idea anyway. And maybe I will try a design which expands on that more drastically.

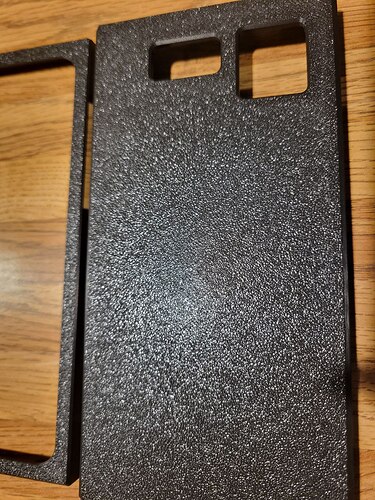

The cutouts could be a little fancier I guess but I was eager to see if I could finish something usable. 2nd try I got the fit perfect. I know the back looks kind of weird, but that’s actually intentional. It’s due to the type of plate it was printed on, but it produces a very agreeable texture. I also have the option of a perfectly smooth back but this is nicer.

I used mostly these flat angles because it’d look cooler. For the buttons it’s fine, but still not sure about the side edges. Rounded is certainly the more intuitive choice and might be nicer when holding the phone for a long time.

This case is definitely a thicc boi (intentionally). The original test print had an even thicker back, but I reduced it slightly for the 2nd try. You can see if you look close that I broke one of the pins taking it apart too fast. I’ll have to experiment with that a little.

It took a lot of time and work to make this, but I’m a little bit in shock at how close to a commercially mass produced product this turned out to be. I really hate the plastic waste that trial tests and failed prints creates, but I don’t think I’ll be stopping here. Way too many enhancement ideas to try… sorry environment. ![]()

Wow. Nice. My head started thinking of enhancement ideas too (or more like, variations and additional feature potentials), but the only thing that really caught my eye were the sharp outer corners - with that mass they will make a dent if the phone falls (then again, we’ve had the discussion before of using L5 for self defense ![]() ).

).

Can you add printing tech specs that you used here too: printer model, printing settings, used material, after printing process (if any) etc.

Yeah I haven’t been too concerned with the protection aspects of the case, for me it’s more about reducing the feeling of holding a hot phone (and it does help). But I should probably look into protections too, because who knows if I drop it some day. (I pretty much never drop phones.) I’ll definitely be reducing the sharpness for next iteration. I think the non rounded bezel on the bottom edges works fine, but I was forced to be a little sharper on the top due to the button cutouts. I’ll have to think about what to do about that.

I guess you mean that it’d make a dent in a floor? Haha, I guess it might. I did think about falls a little bit, and I wonder if the tabs that I have (3rd picture) might actually help protect the phone due to a slight gap between the phone and the case. The corner of the phone is also more rounded than the internal part of the case, so a corner hit would probably protect the phone brilliantly. Not so much your hardwood floor. ![]()

This was printed with a Bambu Lab X1 Carbon. The settings were all defaults! (Which is why these printers are popular I guess - this thing just works. Also keep in mind that 3D printing is new to me.) But if people need that info for other types of printers I think I could get specifics if I know what to look for. Layer height .2mm, 2 walls loops, 15% infill. Not sure what other settings are commonly sought after.

I did nothing at all after printing, this is how it came out. Material was just the PLA Basic that Bambu sells. I don’t know if a different material would be more suitable. I didn’t think I’d get an actual usable thing by the 2nd print!

I can promise that the final version’s going to look amazing. I have some cosmetic ideas that I’m totally excited about but I won’t put spoilers here just yet.

If you’re just printing drafts at this point, I suggest using more coarse settings to speed up printing and save environment. On the final ones you maybe can even increase infill a bit for more hardness (though, I wonder if making case intentionally brittle might actually make it safer for the phone: transfer of kinetic energy to case instead to phone - though, it depends on the overall design, bumpers etc.).

Yes, I was thinking of the floors. Also, feet and toes ![]()