Good. Don’t accidentally delete it  And I suggest adding to community wiki.

And I suggest adding to community wiki.

You could use this:

purism@pureos:~$ ~/guru/temp.sh

cpu-thermal: 33,00°C

gpu-thermal: 33,00°C

vpu-thermal: 33,00°C

bq25890-charger: 29,00°C

max170xx_battery: 31,10°C

purism@pureos:~$ cat ~/guru/temp.sh

#!/bin/sh

for i in /sys/class/thermal/thermal_zone? ; do echo -n `cat $i/type` ': ' ; cat $i/temp ; done | sed 's/ :/:/' | sed 's/: ../&,/' | sed 's/0$/°C/'

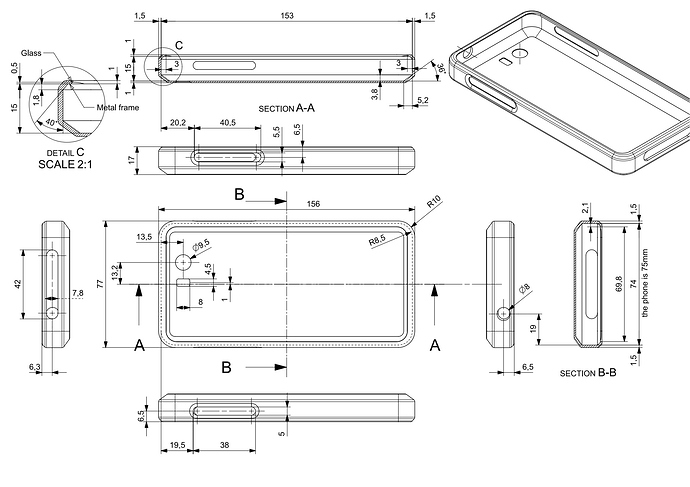

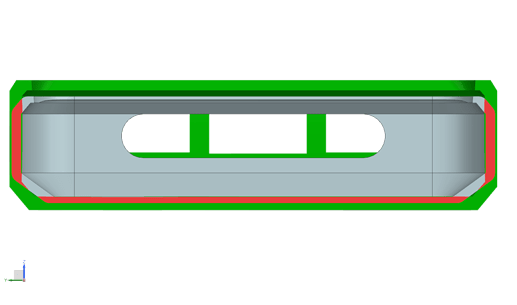

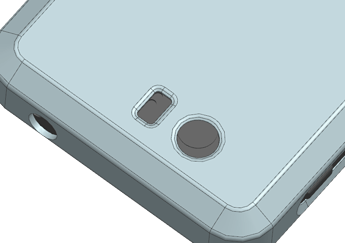

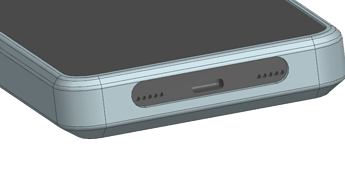

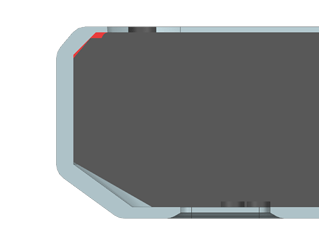

I made some more measurements and defined the model. It’s completely different from the original .stl, but I think it should fit pretty well (how easy it would be if Purism would just share the CAD models of the external of the phone).

It’s still 1 mm less wide than the phone. I suppose that a bit of stretch is needed in order to make it fit well the phone, but I don’t really know how much the material can be stretched. If someone has that data I can modify the model, otherwise someone has to waste some money to test it.

The final result is the following:

I look forward to listening to the comments

I have no idea, knowledge about 3-D printing and also no device for it. But, I’m willing to spent the money (even twice if necessary) and go to a commercial 3-D printing company.

What I would need for this (I do not even know what would be necessary):

- the file to print

- the exact material specification

- the time it will cost (this defines the money to spent, I heard)

- … anything else?

I.e. can someone please be so kind and give me the exact list of detailed information to hand it over to such company.

Thanks

well, it’s true that it looks like it !!!

Good remark, sometimes we miss the simplest ideas !

About material specification, I have used TPU with Multijet Fusion method and a raw finish (smooth or color was out of my budget for a test). The quality is very nice, and about the felling it gives the sensation of gripping as if you were holding a dry sponge.

The cost was around 45$ shipment included and the shipment was received around 15 days later (because I have not chosen the priority shipment).

Hello fiacco, do you mean this STL file ? It has been made by the community, last update was 9 months ago, so I assume it is Evergreen model (we have to check to be sure).

Anyway, I love your last model and help thank you so much

Oh, whoops, yes!

But I think it’s not up to date … or my phone is outdated.

I trust more my measures.

Here is the link to download the stl: https://send.vis.ee/download/3de5814d5ec13cde/#IjH9U0sh9Cn4oaYj87Wm4w

(I registered to the Purism git repo, but my account is awaiting approval from the administrator)

Let us know how it works

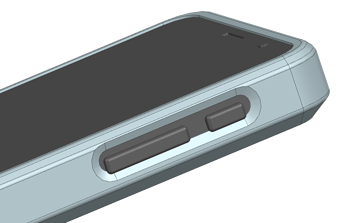

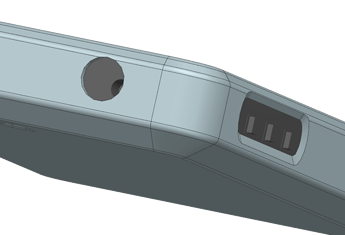

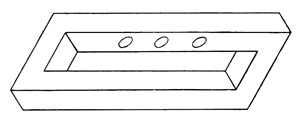

I think I found the original design here, note the holes for the 3 kill switches

:

I’ll print it tomorrow at the library - cost is 0.70€ (<1$), so if it’s not perfect, it’s hardly any loss (I’ll donate it for the cause).

I can also do the infrared measurement of possible heat issues.

Thank you very much for your proposal. Please, just remember that if you print with a “not flexible” filament (like PLA, ABS, etc.), then it can be difficult to put the phone inside the case. If it happen, don’t worry and as a last resort, cut the case at few locations to make it more flexible.

Based on your job, I also trust you more ^^

The issue with the STL I show you was that it has no comment : we don’t know if this is an Evergreen model, nor if the measurements are correct.

Ay, that’s the plan. Works for a prototype. I was already planning on doing some minor surgery to get it in ![]()

And this leads me to a new thought: rigid printing material is more available with hobby printers. It would be nice to have a version that solves the problem already by splitting the case in two. A prototype of this could be just a simple simple cut the length in two and have bit of thin overlap that can be fastened with tape from the back. A more sophisticated version…

A) the bottom could be a “drawer” mechanism that’s attached with rails on the sides or

B) there’s a hinge on the back bottom and it clips to place, or

C) a “giftbox” where the bottom goes inside the frame (overlapping sides), or

D) have only the sides wrap around the sides and on top of the screen edge (not the top or bottom, but they can go above edge obviously) so as to have the material flex a bit and grip the phone (the rigid will have bit of tolerance to do that but may need a couple of prototypes to perfect) [edit to add: this option is something I can test later by modifying the printed prototype]

… and probably a couple of other options.

For bumping (or protection from it) I’d have a bit of material in the corners to attach Sugru/Kintsuglue for a bit of elastic material to dissipate kinetic forces.

Something to think about, maybe.

The 1st company contacted for an offer replied: We can not do Multijet Fusion method (is this something exotic?) and we do not print in TPU due to poor demand of it.

remember that the case is 1 mm narrower than the phone. It wont work.

I don’t know either ![]() . All jokes aside that’s easy to fix, let’s consider it a prototype, I’m sure I’ll have to make some adjustment, I’ll add the comment then.

. All jokes aside that’s easy to fix, let’s consider it a prototype, I’m sure I’ll have to make some adjustment, I’ll add the comment then.

The case is not wide enough for the phone without flex? Well, that’s not good. Any chance you could quickly add 1-1,5mm there to enable rigid plastic use?

If the minor surgery includes sectioning it in half we’ll have the opportunity to check the matching of the profiles

Sure, tomorrow in the morning I’ll post a new version

Edit: CEST

If it’s smaller on all three axis I’d have to cut it to 6-8 pieces and then it wouldn’t be very representative. I was thinking I may have cut it in half just to get it in, not because it wouldn’t fit. Adding a tiny bit all around, so it fit’s like a glove (+0.2-0.4mm all around it, or something like that) would be ideal.

No worries about the time. Preferably before 10 11 CEST would be good.

only widthwise, because it was so the starting file. I imagined that the stretch would allow for a better fit

It probably would. The prototype is good up to a point, to check other measurements - and maybe useful for other forks to develop the case.

Case with X,Y dimensions = phone + 0.2 mm

Front edge slightly reduced