So here I am again for a 3D case feedback !

I decided to take this STL file proposed in the gitlab and not having a 3D printer, I sent it to a professional who uses MJF injection technology, and I chose TPU for its flexibility and at the same time robustness properties.

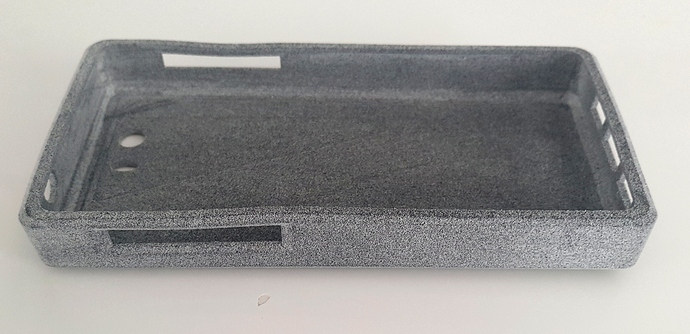

The shell alone:

the 3D printing shell made in MJF/TPU is very impressive: no streaks, no burrs, the holes are respected and the angles too. As if it came from a factory. The thickness of the walls gives an impression of great strength, and the rough texture gives a feeling of grip that I particularly appreciate.

Assembly of the shell on the smartphone:

Dimensions:

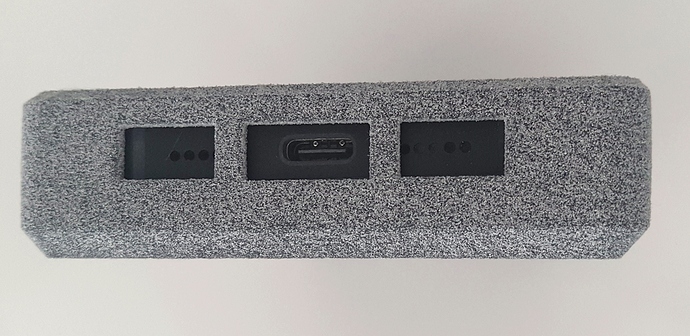

the dimensions are good but not perfect in my opinion. The holes on the sides are such that there is a slight looseness and therefore it does not fit the smartphone 100%. By analogy, to give an idea, let’s say it fits horizontally at 95% without the shell coming off easily. Buttons and switches remain accessible even if you have to make a small effort to reach them (the author of the STL file played on the relief with “chamfers” to facilitate access to the buttons, it’s a good idea), and the USB and audio jack connectors are wide enough to connect cables without being blocked by the shell.

Robustness:

we are not disappointed, the person who made the STL file had the very good idea to cover the relief of the 2.5D screen, which is the most critical part of the device. On several fall scenarios, the shell might protects the smartphone well but there may be scenarios where the screen can break (eg: violently flat, a large part of the shock could be absorbed by the shell, but it may be that the deformation causes a floor-screen contact) and that’s where a glass screen protector can help to absorb the rest of the shock.

Aesthetics:

this is where the real problem lies. I already noticed it a while ago: the corners are almost rectangular, a lot of holes are too, and the thickness makes it look too rectangular and massive in hand / on the table. With this case, we move away from the shape of a smartphone, especially when you stick the device on your cheek to call.

Conclusion:

There are definitely areas of improvement for this STL file. I have in mind a few things to improve:

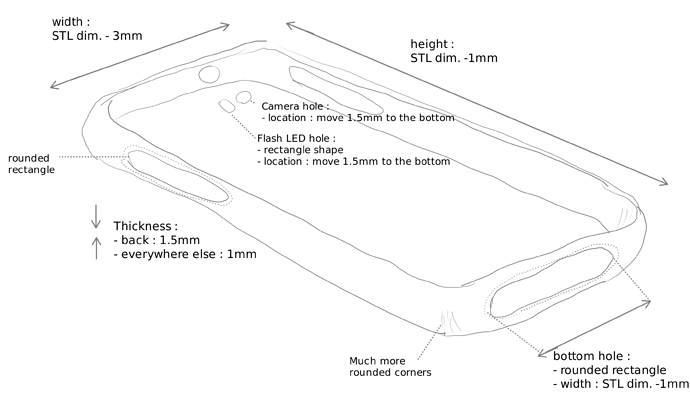

- round the corners at best to avoid the massive rectangular effect

- round all the holes to have a more welcoming design

-

except for the part surrounding the 2.5D screen, reduce the thickness to the strict minimum (1.5mm at the back, 1mm everywhere else) to gain in thinness

- reduce the height (I mean vertically distance jack audio <-> USB type-C) by 1mm

- reduce the width (horizontal distance, I mean distance kill switches <-> vol buttons) of the part of the shell close to the screen (the bottom part is OK) by 3 mm to make the shell more flat against the smartphone

- correct the position of the speaker holes (at the bottom) and the camera holes on the back because they are not aligned:

-

speakers : center toward the USB type-C by 1mm for each hole

-

camera (point of view seeing the back of the smartphone) : correct the hole to 1mm to the right, and 1.5mm to the bottom.

-

flash LED hole: correct the hole to 1.5mm to the bottom, and change the shape from a rugby ball to a rounded rectangle.

- reduce the height of the speakers holes by 3mm

- make rounded chamfers for each hole for aesthetics

If someone knows an open-source and user-friendly (I am a totally beginner) software to help me to modify this STL file, please do not hesitate. If you are afraid that it will take me years to get the software in hand, you can also start making STL updates following my comments!