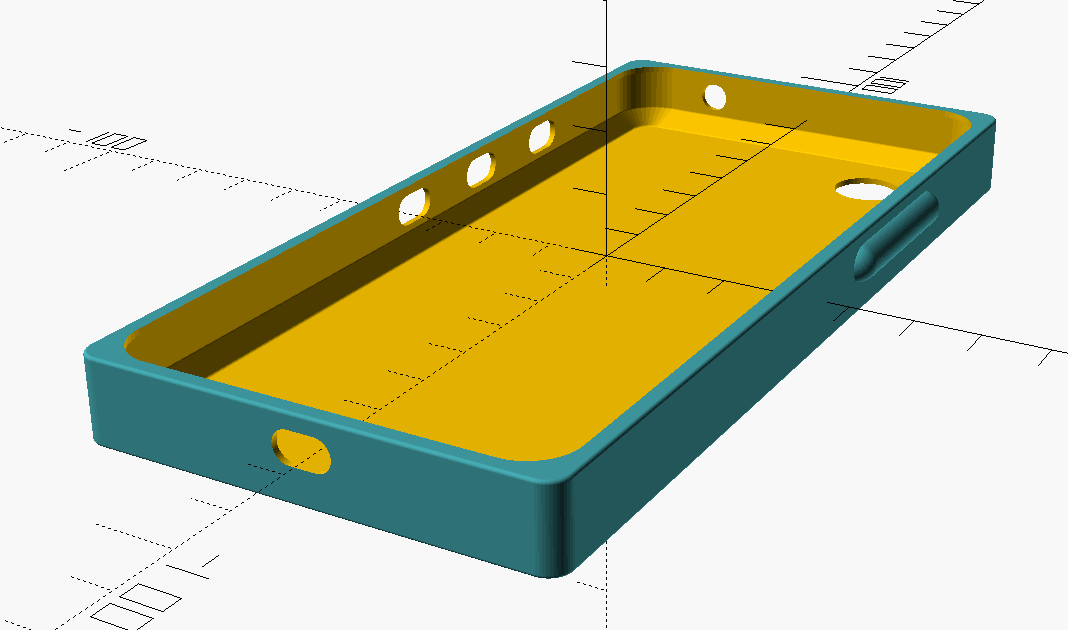

@roguenorm, @Seven, I kind of jumped the gun and started on a cover using approximate measurements from the images on the website. I’m using OpenSCAD, so it will be relatively easy to fix the dimensions when we have them. Once I’ve got the script cleaned up a little more, I’ll put it on Github, and we could start refining/branching designs, etc.